Overview

- Digitalization is the process of harvesting digitized data to effectively transform and improve business conduct

- Digitalization of operations refers to the integration of digital technologies into business operations to improve efficiency, productivity, and accuracy. With digitalization, businesses can automate processes, gather and analyse data, and make data-driven decisions.

Manufacturing Execution System

No matter the size of a manufacturing operation, an MES can contribute to overall productivity and profitability by making the manufacturing process information driven. Companies must adhere to strict regulations to ensure traceability compliance

Benefits of MES

- Improved quality control: As quality control information is transmitted in real time, companies with an MES can immediately halt production as soon as issues are identified. This reduces waste, scrap, overages, and re-work.

- Increased uptime: An MES generates realistic production schedules by balancing personnel, material, and equipment resources. It integrates scheduling and maintenance to maximize product flow and asset utilization – increasing uptime and improving overall equipment effectiveness (OEE).

- Reduced inventory: A manufacturing execution system updates inventory records with new production, scrap, and non-conforming material so that your purchasing, shipping, and scheduling departments know exactly what material is on hand at all times. This reduces just-in-case inventory and work-in-progress (WIP) inventory – saving money on manufacturing, transportation, storage, and inventory monitoring.

- Paperless shop floor: Eliminating paperwork means there is less chance for human error. It also means that the data recorded from the shop floor is immediately available to decision-makers across all integrated systems, to inform real-time decision-making.

Improved product tracking: An MES follows the entire production cycle from beginning to end, grouping final parts or batches with the corresponding manufacturing data. Thi s data allows for improved regulatory compliance for manufacturers that must conform to government or industry regulations.

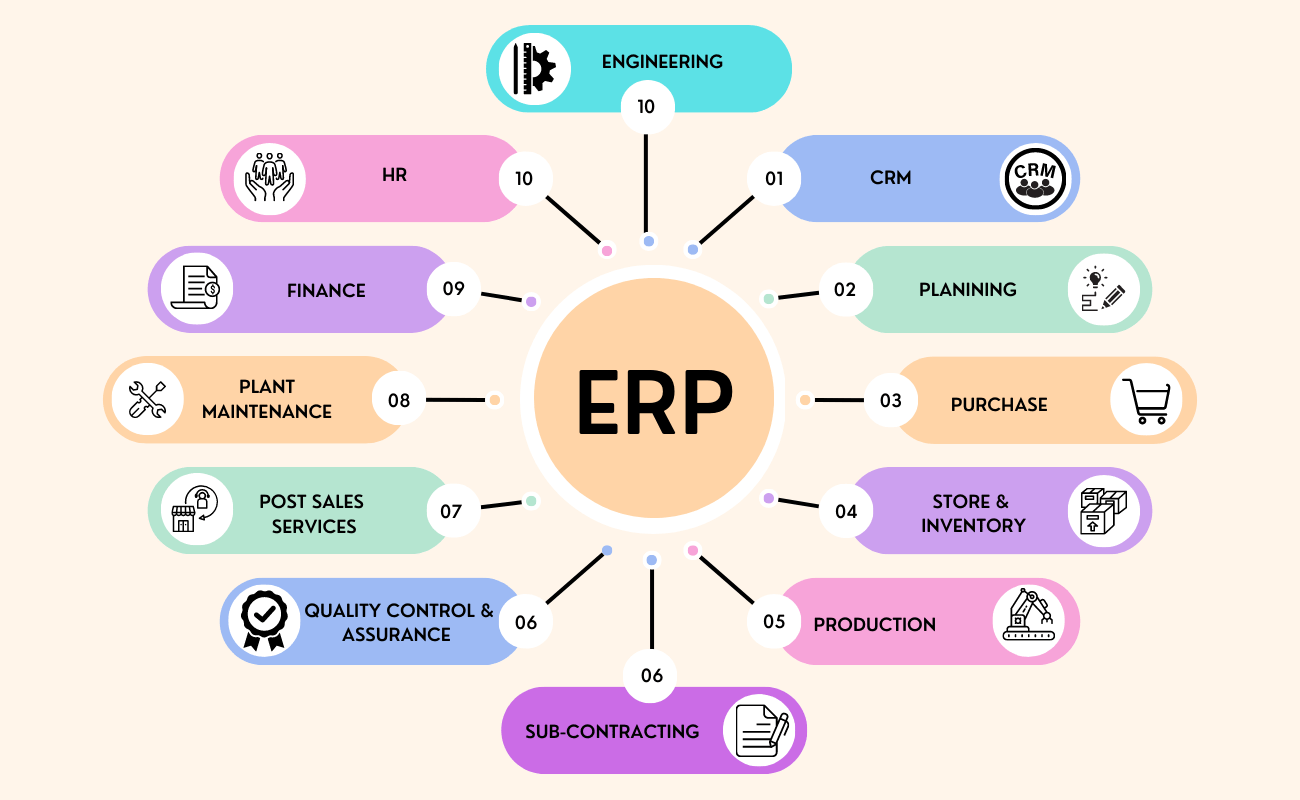

ERP Implementation Strategy & Support

- The ERP implementation strategy is a major decision for company executives and stakeholders to make. The implementation strategy describes the plan for change that ensures alignment with overall corporate objectives and goals

- The strategy defines the organizational principles and approach to executing the ERP implementation

- Implementing a new ERP makes it easier for employees to collaborate on projects or access information when they’re not at their desks.

- Manufacturers are increasingly turning to cloud-based ERP systems to streamline their operations. These systems enable manufacturers to access the same tools they use in their offices, allowing them to spend less time on paperwork and more time focusing on what they do best: creating products.

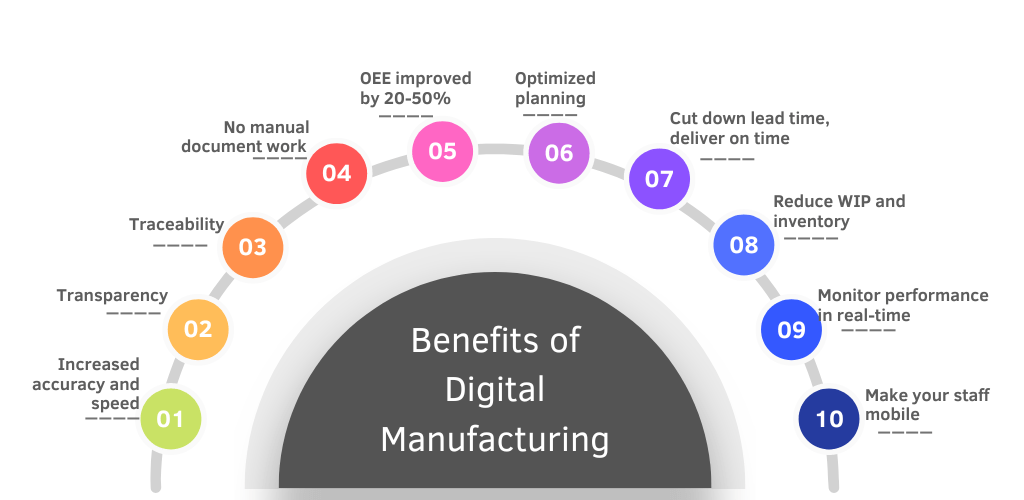

What you get by digital manufacturing

- Increased accuracy and speed

- Transparency – everybody gets access to the same real-time data

- Traceability – every step of the process can be tracked easily

- No manual document work – meaning no waste of time

- OEE improved by 20-50% – if you know where exactly and why you are wasting resources allows you to take all the necessary actions to improve your overall performance.

- Optimized planning – producing only what’s needed when it’s needed. You can easily create the perfect production plan. No more overproduction.

- Cut down lead time, deliver on time

- Reduce WIP and inventory – don’t tie up your cash in the inventory. Analyze your current production and identify your weak points. Monitor your stock and the overall material flow.

- Monitor performance in real-time and spend less time reporting