Overview

Planning of greenfield factories and restructuring of brownfield factories by following the principles of ideal material flow and optimized process design. We develop the complete factory planning from the early target definition until the start of production. Our expertise at your disposal: together we are planning your project from rough concept over detailed design to realization – economically useful and technically feasible . Ideal factory and process flows following lean principles as basis for your factory development – we develop your customizable factory structure plan.

Turnkey solutions

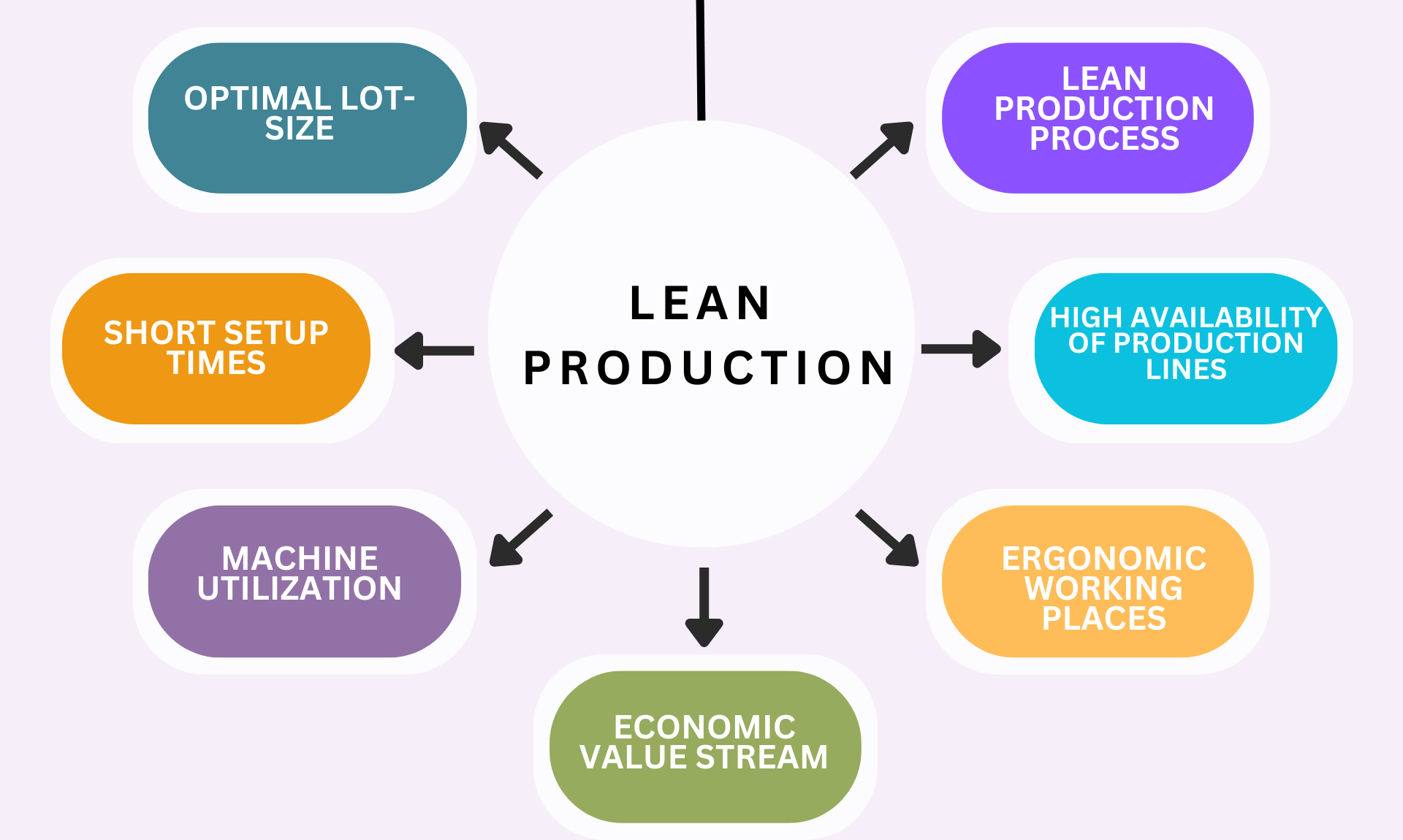

WE DESIGN YOUR LEAN PRODUCTION

A comprehensive process analysis is the first step to achieve an optimal Cost/ Benefit Ratio along the entire production process.

Benefits

1. More consistency: Unlike people, machines don’t have “off” days or erratic break patterns, so results are constant and predictable.

2. Reduced waste: With automation, you calculate exactly how much of a material you need and avoid having too much left over.

3. Improved productivity: By streamlining and automating processes, you fine-tune production lines, working faster and better.

4. Better quality: Not only do you cut out the risk of human error, but you can also continually tweak automated processes to enhance the results.

5. Safer working conditions: Factories are accident-prone hot spots, but the more your equipment can sense potential dangers and shut down accordingly, the more you can control the risk.